Corrosion Monitoring Unit

Safeguard Your Assets with our Corrosion Monitoring Units

Grok is a trusted specialist in advanced corrosion monitoring systems, delivering reliable solutions to protect critical infrastructure from corrosive damage. Our corrosion monitoring units are engineered to detect, measure, and analyze corrosion activity in real time, supporting a wide range of applications including data centers, water treatment facilities, wastewater treatment plants, industrial manufacturing sites, petrochemical plants, pharmaceutical facilities, food processing environments, and commercial buildings.

Active Corrosion Monitoring Unit

CORROSENSE Active 2.0 is an advanced device designed to monitor and store real-time data on air corrosivity within indoor environments. This innovative unit provides crucial protection for sensitive electronic components by actively detecting and tracking corrosion rates in the air, enabling timely intervention and maintenance. Using Electrical Resistance (ER) technology, the CORROSENSE Active 2.0 measures metal tracks’ electrical resistance to atmospheric conditions, providing precise corrosion rate calculations. The device complies with the ANSI/ISA-S71.04 Environmental Conditions for Process Measurement and Control Systems: Airborne Contaminants standard, ensuring reliable and standardized measurement of corrosive air conditions for electronics and electrical equipment.

Key Features

- Real-time corrosion monitoring for proactive maintenance.

- Interactive and user-friendly software for easy data access and analysis.

- 5″ LCD touchscreen display for convenient on-device monitoring.

- Replaceable copper and silver sensors for detecting specific corrosive agents.

- Replaceable temperature, pressure, and humidity sensors for comprehensive environmental analysis.

- Power input options via Ethernet (PoE) or C-Type Adaptor.

Principle of Operation

- The AQOZA CORROSENSE Active 2.0 employs ER technology to directly measure the electrical resistance of exposed and unexposed metal tracks. By calculating the corrosion rate, the device categorizes severity levels according to the ANSI/ISA-S71.04 standard:G1 – Mild

G2 – Moderate

G3 – Harsh

GX – Extreme

The corrosion severity is represented in angstroms for copper and silver sensors, with real-time measurements allowing for predictive maintenance and enhanced equipment reliability.

Benefits of Online Corrosion Monitoring

- Detects corrosive gases in real-time to minimize risks.

- Reduces hardware failure rates by providing actionable data on corrosion levels.

- Supports predictive maintenance for air handling and filtration systems.

- Ensures compliance with environmental and operational standards for critical facilities.

Key Features

Thermo fans are the first choice for high air flow temperatures and harsh operating conditions. They are the smart choice when expectations are higher than average, in applications such as extraction from kitchens, process air systems and industrial ovens. Depending on the model, they are suitable for continuous air flow temperatures of up to 200°C.

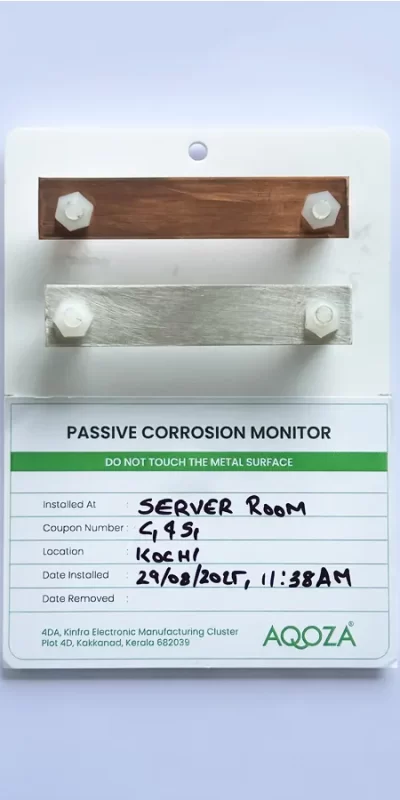

Passive Corrosion Monitoring with Corrosion Coupons

Corrosion Coupons provide a passive, reliable method for monitoring indoor corrosivity levels. These advanced corrosion coupons, based on Electrical Resistance (ER) technology, are designed to assess corrosion passively in sensitive environments. The monitoring process involves placing corrosion coupons in the field for a period of 30 days. After exposure, the coupons are returned to AQOZA’s laboratory, where the amount of corrosion on copper and silver films is measured by analyzing the electrical resistance of both exposed and unexposed metallic films. This method adheres to the ANSI/ISA-S71.04 international standard for measuring environmental corrosion levels, ensuring accurate and standardized results